From Wood Procurement to Crafting Our Original Products

●Wood Procurement

We source our wood in its raw log form from premium timber markets, where high-quality solid wood is gathered. Acquiring wood requires a keen eye, and at B-Labo, we collaborate with Teramoto Mokuzai, a company with decades of experience in the lumber industry in Yoshino, the wood’s place of origin, to ensure the finest selection.

Additionally, there are instances where we competitively bid for wood at product markets.

●Lumber Processing (Rough Sizing)

From logs, we carefully assess the condition of the wood and employ a process known as ‘wood selection’ to cut the lumber, ensuring the right wood is used in the right place. Immediately after felling, wood contains high moisture content, leading to contraction, expansion, and susceptibility to warping. To counteract this, we cut the lumber slightly larger than the required product dimensions.

●Drying

We subject the wood to outdoor drying for over a year and follow it with indoor drying for another year or more.

Immediately after felling, wood contains a significant amount of moisture within its fibers, which gradually evaporates over time. During the drying process, wood may undergo contraction and deformation. Ensuring proper drying is crucial to prevent warping or twisting in the final products. The moisture content varies among different types of wood, but to make wood suitable for various applications, it must be dried to a moisture content of less than 20%. At Teramoto Mokuzai, we emphasize natural air drying, taking over two years to dry the wood before crafting the final products.

By allowing wood to slowly dry through the forces of nature, we can maintain its color, luster, and exquisite aroma. Additionally, maintaining the right moisture content results in wood with strong fibers, high durability, and reduced susceptibility to cracking, producing high-quality lumber.

●Lumber Processing (Final Milling)

After logging, processing, and drying over an extended period, each piece of well-seasoned material is individually reworked using a machine called a ‘molder’ to straighten and shape it to standardized dimensions, addressing any warping or bending.

It is only after this stage that the material becomes ready for actual use.

We can further refine the surface of the wood, achieving a beautiful finish according to your preferences, using planers, sanders, and specialized tools.

●Creating Original Products

Our finished milled products are not only available for sale as DIY and construction materials but are also used to craft original items that showcase the unique qualities of Yoshino wood.

Many of our original products are one-of-a-kind, which means that stock availability may vary.

We may be able to recommend the most suitable products and purchasing options to match your preferences and needs. Please feel free to reach out if there’s anything we can assist you with.

Our Passion for Product Development…

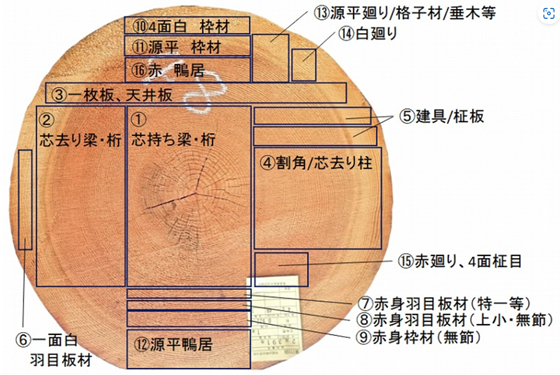

Yoshino wood has been primarily used as a premium building material, including in architectural structures, doors, thresholds, lintels, decorative panels, and more.

Our customers mainly consist of construction firms, carpenters, and wholesalers.

In recent years, the use of wood in housing has decreased due to changes in architectural styles. However, wood remains prevalent in everyday life, with much of it being inexpensive imported lumber. It is likely that only a very small fraction of people truly appreciate the value of wood, and most people do not even know (or are not interested in knowing) what type of wood is used in their surroundings. This is not a negative judgment but rather a reflection of the fact that many individuals lack opportunities to engage with wood or learn about it. The reality is that there are very few accessible places for the general public to purchase domestic wood.

Despite Japan’s status as a forestry-rich nation, the country’s failure to utilize domestic wood has led to a decline in the forestry and timber-related industries. Even when it comes to harvesting, there are no outlets for the excess wood that fills our mountains, including the Yoshino region.

Our mission is to bring domestic wood closer to people and make them aware of its charm by developing products filled with the allure of Yoshino wood that are easily accessible. While it takes over two years from wood procurement to product completion, it also requires over 80 years and four generations of dedication for the wood to even appear in the raw timber market. We are grateful to the ancestors who nurtured these trees and, with their spirit, we deliver a life enriched by the presence of these wonderful woods to our customers.

-e1712842507106.png)